After finishing my first couple of wood carving projects I was looking for the next one. I had seen a few spoon carving DIY posts about carving spoons so I decided to try it out. I also happened to need some new big kitchen spoons for cooking.

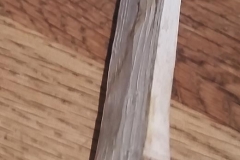

After spending a minute on Amazon I opted for a two sided hook knife from Morakniv. I chose this specifically because both sides of the blade have an edge, and since this is my first and only dedicated carving knife, I wanted to make sure it would do as much as it could.

The next night while eating dinner my girlfriend got an invitation to, of all things, a spoon carving party. The hosts are avid outdoors-people and one is particularly into wood carving. Of course we agreed to go, and of course I told everyone about how crazy the timing was for me. Unfortunately my knife didn’t come in time for the party, it was waiting for me when I got home, so I used some of his knives during the party.

The idea of the party was that before anyone would eat, they would carve a spoon. Fortunately for the guests, they didn’t hold us to that. We may not have eaten until midnight if they had.

We got to work pretty much right as we walked in. I grabbed what turned out to be a piece of cedar to carve, which was fortunate because it was one of the easier pieces to carve. In fact, I was the only person, save for Luke the master carver and host, to finish a spoon by dinner.

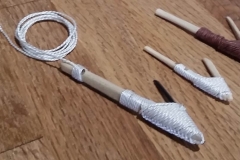

Seeing my spoon while we ate, everyone who had at that point given up on carving decided that they wanted to finish. After eating we all had a second go at carving. I picked up a second piece of mystery wood and starting working. This piece is darker and noticeably harder than the cedar. I got a good way through, but did not finish that night. Fortunately I had to tools to finish it at home.

Over the next week I would put a little bit of work in at a time while watching TV. The result is a much sturdier, but also much more refined spoon. It looks like it will be a really good soup/ramen spoon.

I did a quick sanding on the cedar spoon, which gave a cool dimpled pattern by only subtly breaking the edged of each cut. For the darker spoon I will sand out the inner bowl, but leave the hand carved finish for the rest. They will both get some mineral oil to seal the wood, then they are ready to go.

You must be logged in to post a comment.